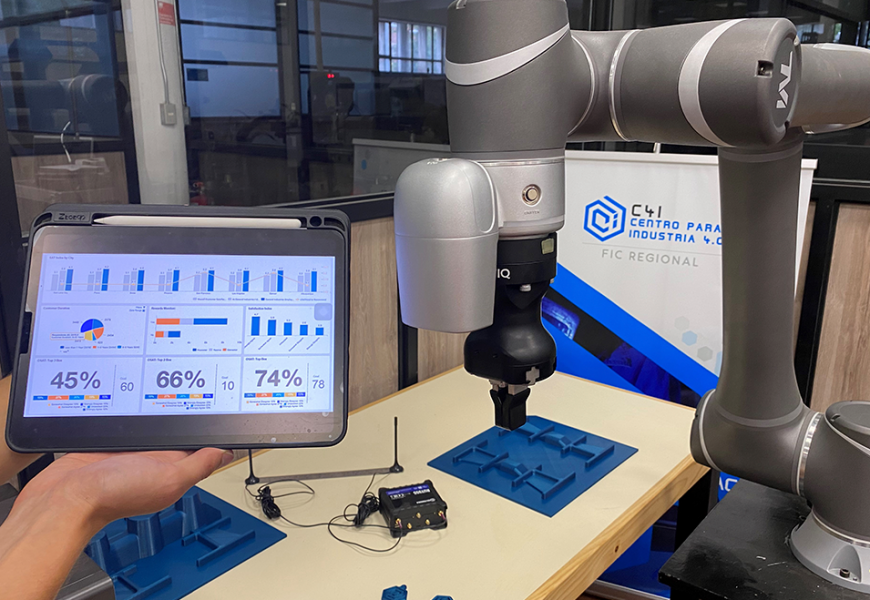

The Center for Industry 4.0 of the Faculty of Engineering at the UdeC together with the Regional Government of Biobio developed a project to support manufacturing SMEs in the region. They already have more than a hundred companies diagnosed and a 100% free training portal.

By Lucas Tapia / lucastapia@udec.cl

/ Graphics: Lucas Tapia

The Biobio region has been characterized as a manufacturing region par excellence, being the industrial sector that contributes the most to employment and reaching a share of 24% of the regional GDP. However, the existence of large gaps related to the low percentage of sophisticated tools, the limited capacity for technological innovation and the low level of automation of manufacturing processes has been evident.

Therefore, it is that the Center for Industry 4.0 of the Faculty of Engineering of the Universidad de Concepción and the Regional Government of Biobio developed the “Technological Unit for the manufacture of complex and advanced products”, a project financed by the Fund of Innovation for Regional Competitiveness of the Regional Government of Biobio (FIC-R) with the goal of supporting small and medium-sized manufacturing companies in the region, so that they know -and potentially incorporate- advanced manufacturing processes in order to generate advanced capacities to enrich human capital, strengthen and enhance a relationship of work and support with the academy, especially understanding the current context of the pandemic and the difficulties that some companies are going through due to this situation.

The program began at the end of 2019 and it has a two-year development period in different stages. The initial stage consisted in a process of gathering information through an online diagnosis, to which regional SMEs from the metalworking, non-mechanical and wood manufacturing sectors were invited.

A total of 94 companies of different sizes participated and the main gaps in the industry were identified, which made it possible to better guide the training processes. Information associated with collaboration, human resources, manufacturing techniques used and innovation was obtained.

Among the main results, the most relevant is that only 23% of the companies that answered the survey consider themselves innovative, with a low dedication of resources for these purposes. With regard to collaboration, 24% state to have carried out joint projects with knowledge centers in the last five years. Also 23% of the companies have hired specialists with a master’s or doctorate degree; however, this type of worker only constitutes 7% of the total number of employees and they are mostly concentrated in administrative positions.

Lastly, regarding the use of technologies, 67% declared having incorporated and regularly used CAD digital design processes, and from the 42% who declared having CNC equipment, the majority concentrated on cutting tables and machining centers. In regard to management skills, the ability to manage and monitor high uncertainty projects was identified as one of the main weaknesses, which increases the barriers for the development of innovation projects.

All these results help to construct a report of detected gaps which is published on the Center’s website (http://c4i.udec.cl/) and they allowed channeling efforts to provide support to regional manufacturing SMEs. Along these same lines, the creation of a free online training portal is highlighted, focused on covering the most important topics that were evidenced in the diagnostic process and its contents are organized in 60-120 minute sessions with certification at the end of the program.

For more information, please contact: bgermany@udec.cl

Last modified: 29 de agosto de 2025