By awarding Corfo funds from the “R&D Challenges for Sustainable Productive Development” program, the University of Concepción is progressing in developing processes to produce emissions-free copper and high-purity metallic lithium, two key initiatives in the transition to sustainable mining.

By: Verónica Gormaz Muñoz, Journalist – Faculty of Engineering vgormaz@udec.cl | Images: Courtesy of Directorate of Communications – University of Concepción

The main objective of the two projects that the University of Concepción was awarded in the recent innovation challenge promoted by the Production Promotion Corporation, Corfo, is moving towards more efficient and environmentally friendly mining through the “R&D Challenges for Sustainable Productive Development” fund.

In this line, the projects awarded by UdeC, which include resources for 16 million dollars, stand out for their strategic contribution: the first, “Li-DIMET Nucleus: development and scaling of sustainable processes for the production of metallic lithium in Chile,” a unique process in Latin America for the production of the valuable metallic lithium; the second, Development of a new process for copper concentrates without emissions and slag,” technology capable of producing emissions-free copper.

It should be noted that, at present, Chile is the world’s largest copper producer, with almost 24% of global production, and is the second largest producer of lithium, with more than 39 million tons extracted in 2022, according to the institution’s data. There lies the importance of supporting this industry through technological innovations.

Metallic lithium for the energy of the future

The Corfo Board awarded seven projects in this first call, allocating US$41.8 million from the lithium contracts with SQM and Albemarle. The initiatives, focused on lithium, battery reuse, and sustainable mining, will be developed mainly in the Biobío, Tarapacá, Antofagasta, and Metropolitan regions.

Specifically, the first initiative awarded by the University of Concepción, with a contribution of US$6 million, aims to develop new technologies for producing sustainable metallic lithium. This project, which will be run together with SGS Minerals S.A, Commissariat à l”énergie atomique et aux énergies alternatives (CEA), and Usach, aims to transform the production of metallic lithium, an essential resource for batteries used in clean technologies such as electric vehicles and renewable energy storage.

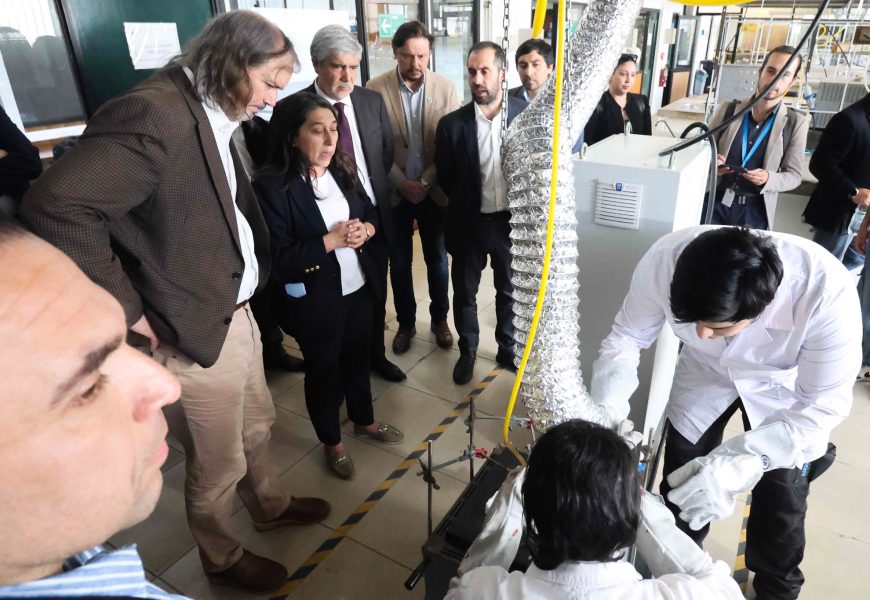

The project is led by Professors from the University of Concepción’s Department of Metallurgical Engineering, Dr. Eugenia Araneda Hernández, Dr. Víctor Parra Sánchez, and principal investigator Dr. Eduardo Balladares Varela, head the Li-DIMET Core, focused on the development of research and innovations in the field of metal knowledge.

This work already has tangible achievements regarding the generation of this strategic metal, which is projected to be used shortly as a raw material for the elaboration of the so-called second-generation batteries and seeks to position the Chilean lithium industry as a reference worldwide.

Dr. Araneda, the academic in charge of leading this initiative, highlighted that “it is the most relevant milestone since the creation of our degree program. These are tremendously important resources, but in addition to economic resources, they allow us to make what we do as a group visible. This is a tremendous backing.”

Zero waste, zero emissions

The second awarded project focuses on reducing emissions in the processing of copper concentrates using Green Hydrogen (H2V). It seeks to develop a technology to process copper concentrates without emissions and slag. Thus, using hydrogen as a reducing agent and through circular economy approaches, technologies will be developed and validated that seek to lead the mining industry toward cleaner and more responsible models.

With a contribution of US$10 million, this initiative aims to benefit the environment and move towards more competitive, resilient mining with sufficient independence from other countries in critical processes essential for the country’s productive development.

This technology, initially presented by Dr. Igor Wilkomirsky Fuica, is currently being developed at a semi-pilot level or TRL 5 and starting its scaling process thanks to this new pilot plant that will be built at the University of Concepción. It is also expected to implement an industrial demonstration plant (or TRL 8) at a mining site. In March 2022, it received the national patent from INAPI and initiated the international patenting process in 10 countries with copper markets.

Dr. Wilkomirsk explained that this is “a technology with a zero or even ‘negative’ carbon footprint due to the surplus of high-pressure steam it generates, which can be converted into clean energy in the application. We actually try to recover metals currently being lost, such as high-value molybdenum, and not generate slag, which is one of the existing technology’s problems. We also try not to pollute the environment. In this way, it has advantages over current technology, both environmentally and economically.”

In this context, Dr. Roberto Parra Figueroa emphasized that with this project, “we are addressing a problem that is important for the country, which is to give the possibility of producing copper, refining copper in Chile in a much cleaner way, with greater added value and with the valorization of all the elements that come in the concentrate.”

Last modified: 3 de septiembre de 2025