It is unusual to eat something blue. Nature, full of colors, offers few natural pigments in those tones. On the other hand, the processes for creating new dyes need to be sustainable. These are two challenges that the Interdisciplinary Marine Biotechnology Group (GIBMAR) took as a challenge to form the spin-off Coloris Biotech and offer a solution for the food industry.

By: Soledad Toledo, Journalist VRID UdeC / lucabrer@udec.cl | Images: Thanks to Coloris Biotech

The first thing that invites us to eat food is its color. We prefer food with bright and intense tones, as it suggests freshness and quality. For this reason, the industry needs to find dyes that make their products eye-catching. For years, it has opted for synthetic dyes, which have advantages over natural dyes, such as low costs and resistance to temperatures and pHs used to pasteurize food.

However, artificial dyes, such as bright blue, allura red, and twilight yellow, have been withdrawn and banned in several countries. Today, large companies have set international challenges to find formulations that replace these additives with natural alternatives, which are also sustainable solutions.

And it is quite a challenge to obtain natural blue dyes. “That’s where the saying comes from: the one who wants blue suffers the blues,” says Dr. Jorge Dagnino Leone, smiling. “It’s a costly pigment. The pharaohs used it but from lapis lazuli. It was obtained from mineral sources.”

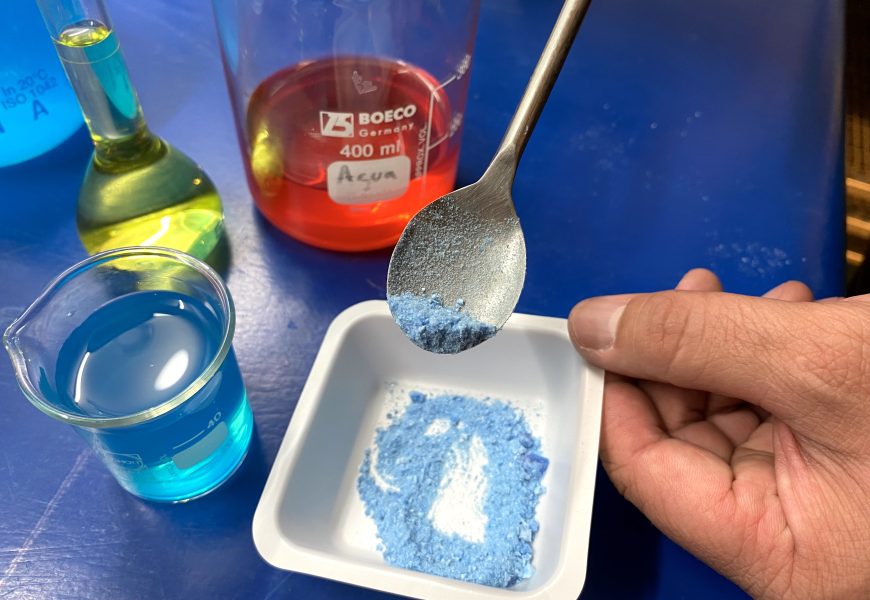

During his PhD, Dagnino analyzed the proteins associated with red algae pigments, in particular a rare protein: allophycocyanin. In the laboratory, he isolated it and replicated it in bacteria, thus finding a new way to obtain blue and red dyes and their mixture. “Algae produce a blue pigment as an accessory component to photosynthesis. So, if natural blue colors are lacking, we can make them and produce them faster than current sources. We have to see how to take advantage of it.”

Dr. Dagnino joined the Interdisciplinary Marine Biotechnology Group (GIBMAR, in Spanish), led by Dr. Cristian Agurto Muñoz, an academic from the Faculty of Pharmacy and the Biotechnology Center of the University of Concepción. This team has progressed in developing several technologies related to the use of algae. “Dye technology has been in development for several years, and we are still working on it,” explains Dr. Agurto, but he clarifies: “What still needs to be solved is no longer the technological challenge, but rather an industrial scaling, with rules and regulations defined in Chile and abroad, and that have an established time for progress.”

The laboratory was no longer enough for the next stage, so how should we proceed to bring this technology to market?

Betting on groundbreaking results

This innovation implies a change in the paradigm of how dyes are manufactured. Muriel Sandoval Latif, Manager of the Transfer and Licensing Office (OTL UdeC), says: “It is difficult for a company to assume the risk of taking on a technology that is at a pilot or laboratory stage, and that they want to do the whole journey to reach the market. So, I suggested that Professor Agurto form a spinoff so that they could mature and scale it themselves because they can do so.”

Dr. Agurto explains the progress towards this new stage: “A crucial element to dare to do this is to be convinced that these technologies have a value and an economic and social impact. Maturing research projects support these developments; today, we see that they solve a real problem.”

Another element is the support of the University of Concepción, which, starting in 2019 with the Regulation of Technology-Based Companies, gives impetus to this type of venture based on technologies developed by UdeC academics and academics. Agurto points out that another key is the team’s spirit: “There is a common denominator in us, which has to do with taking the risk and moving forward; this is essential to make these types of decisions.”

Thus, Coloris Biotech was created in 2022. It allowed them to apply for projects like the Start-Up Ciencia and Semilla Corfo. “With these funds, we advanced from a TRL* 2 to 5, solving several technical challenges, and on the other hand, we have also made progress in the commercial and regulatory area, following these three paths so as not to fall behind in any area,” says Muriel.

In 2024, they were awarded a new Start-Up Ciencia fund, allowing them to scale production volumes, optimize costs, and make the dye profitable. “We know that it works; what we are looking for is to make it a more intense color and improve its formulation. We are working with people from the food area to offer a blue color for alcoholic cocktails, isotonic drinks, and functional waters.”

It is a long road, but the team behind Coloris have learned that it is necessary to tune in to companies’ real needs so that technologies can be adopted. Dr. Agurto summarizes this route as “Dream, create, persevere, have a purpose, and achieve strategic development.”

*TRL: “Technological Readiness Level” is a concept developed by NASA to identify the state of advancement of technology, using a scale from 1 to 9, ranging from basic and conceptual principles to the implementation of the new technology in real conditions.

Last modified: 3 de septiembre de 2025